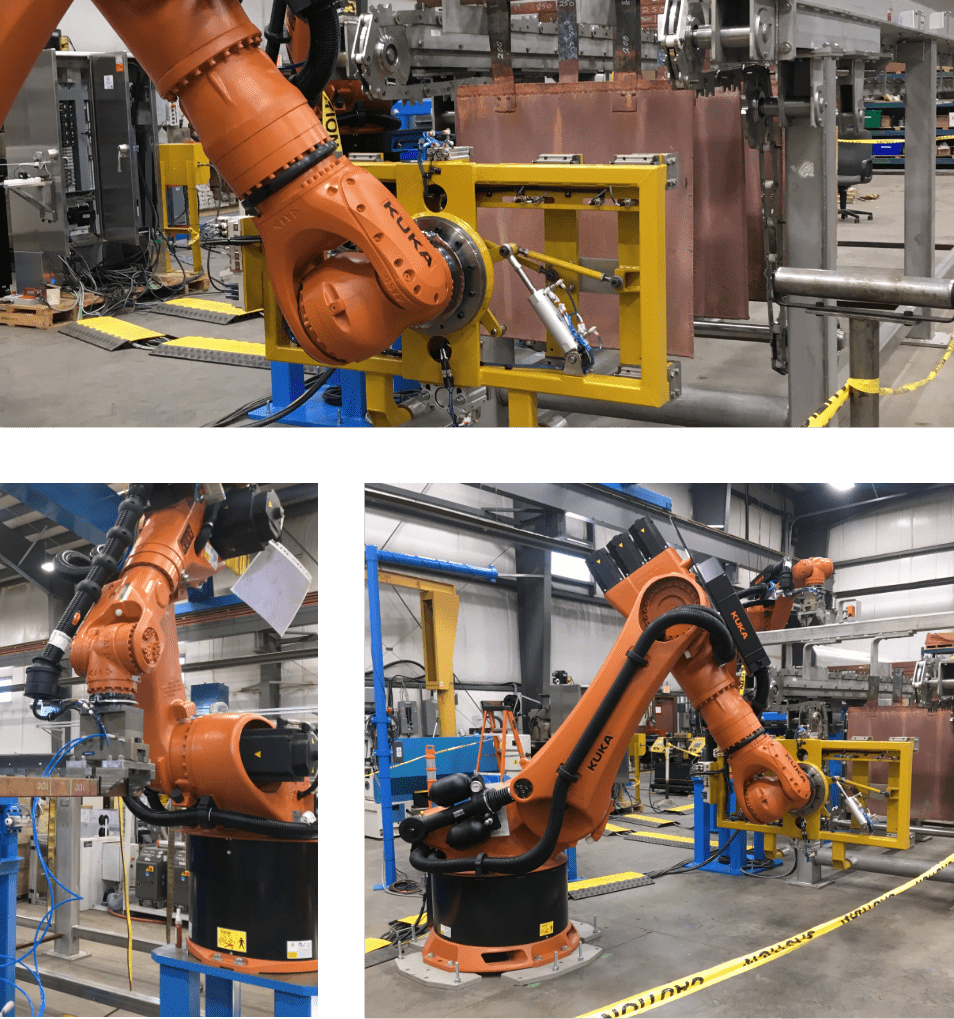

Starter Sheet Cathode Harvesting

Millions of tons of copper are harvested each year from starter sheet refineries. The process of removing bars from the cathode is often done manually, which is a time consuming process. Bulk processes can speed up production, but increase the risk of damage to hanger bars.

With Ionic’s harvesting machine, you can continuously harvest cathodes without any risk of damage whatsoever. What’s more, our machine will stack your copper sheets in perfectly square bundles, ready to be shipped.

By automating the harvesting process with robotics, our system increases output, improves quality control, and reduces safety risks for your team. It can be adapted and integrated into virtually any existing infrastructure.

For instance, do you use a bar rack to load into your cathode assembly machine? We’ll modify the harvester to work with your existing rack, so that you can move your hanger bars from harvesting directly into assembly with no in-between step.

By implementing our bent bar detection system, you’ll also be able to weed out any damaged bars and improve your plant’s efficiency and quality control.

Base System

- Sheet bundling (by height, weight, or number of cathodes)

- Removable bar rack

- Crane bale alignment

Optional Features

- Bar cleaning

- Bent bar detection and rejection

Get Your Risk-Free, Zero-Obligation Quote